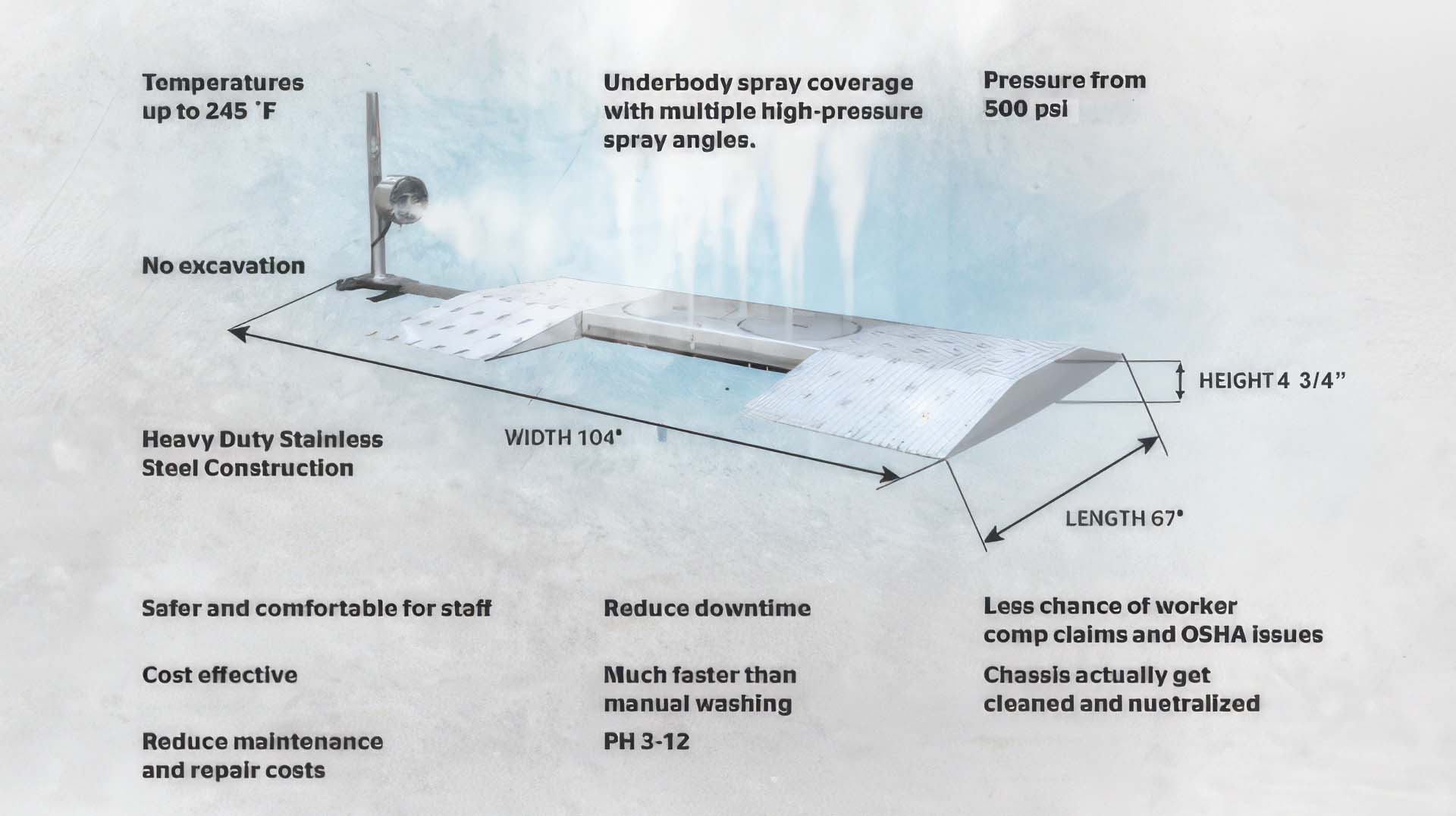

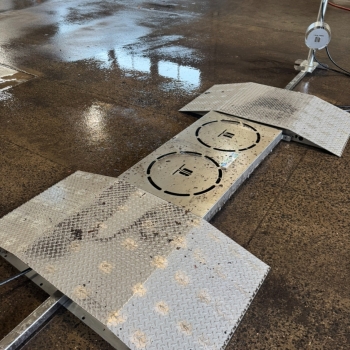

Instruct your staff to drive over the SaltWash Chassis Wash system slowly, and it automatically cleans the corrosive salts!

- No safety issues.

- No comfort issues.

- No time-wasting issues.

- No complaints.

You simply drive over the fully automated system and let the SaltWash Chassis Wash do the work. NO Excavation Required!

Call 914-668-7220 or contact us today, and we can help you make this easy solution a reality.